|

Up, up but not away

Building Magazine 2006 issue 02

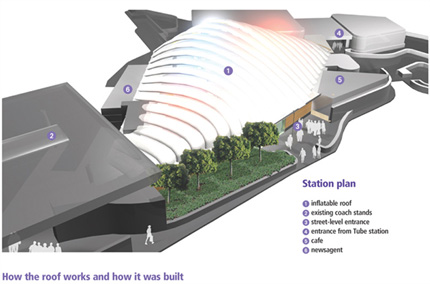

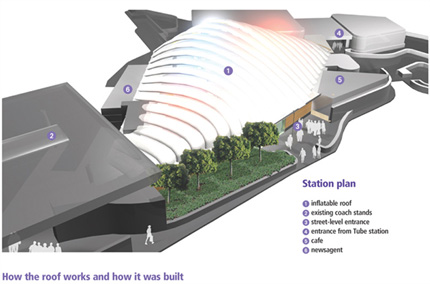

The world’s first permanent inflatable roof has just landed at Heathrow airport. Before it got there, a project team including a hot-air balloon specialist had to design it, build it and get it past the regulators. Thomas Lane finds out how they made sure it didn’t fly away

The inflatable roof at Heathrow

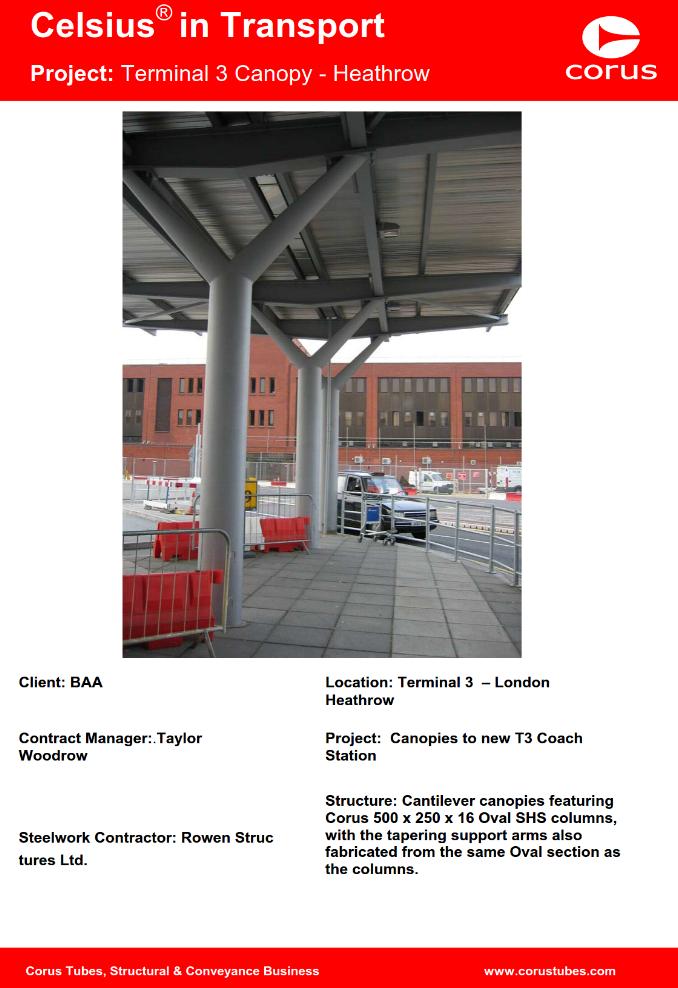

The latest attraction at Heathrow airport isn’t another mega-terminal but a giant inflatable armadillo. It could prove to be a welcome diversion for nervous or fractious children coming in to land because its ribbed surface looks just like an inviting bouncy castle. But the kids will be disappointed once they discover that it is in fact the roof of the National Express coach station.

Construction professionals, on the other hand, are likely to be delighted. This is the world’s first permanent inflatable roof and its advantages mean we could see many similar eye-catching structures. The team took a risk with this untested technology because they believed it to be the ideal solution for a difficult site. Coach operator National Express wanted to create a 1100 m2 column free, covered departures lounge from an existing, open space. Just to make the job more tricky, there was nowhere to put the foundations for a conventional structure because one of the airport’s Tube stations is underneath the site.

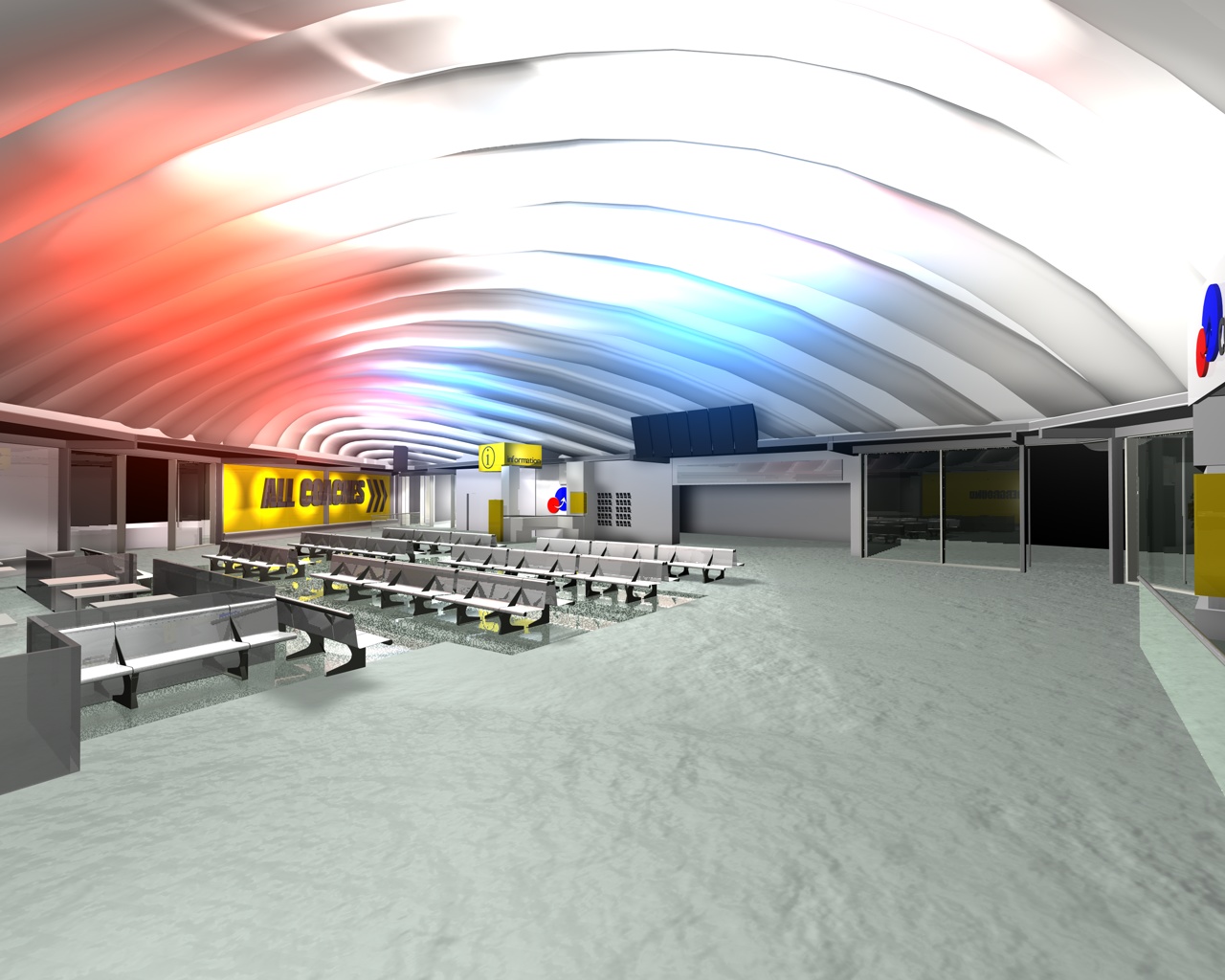

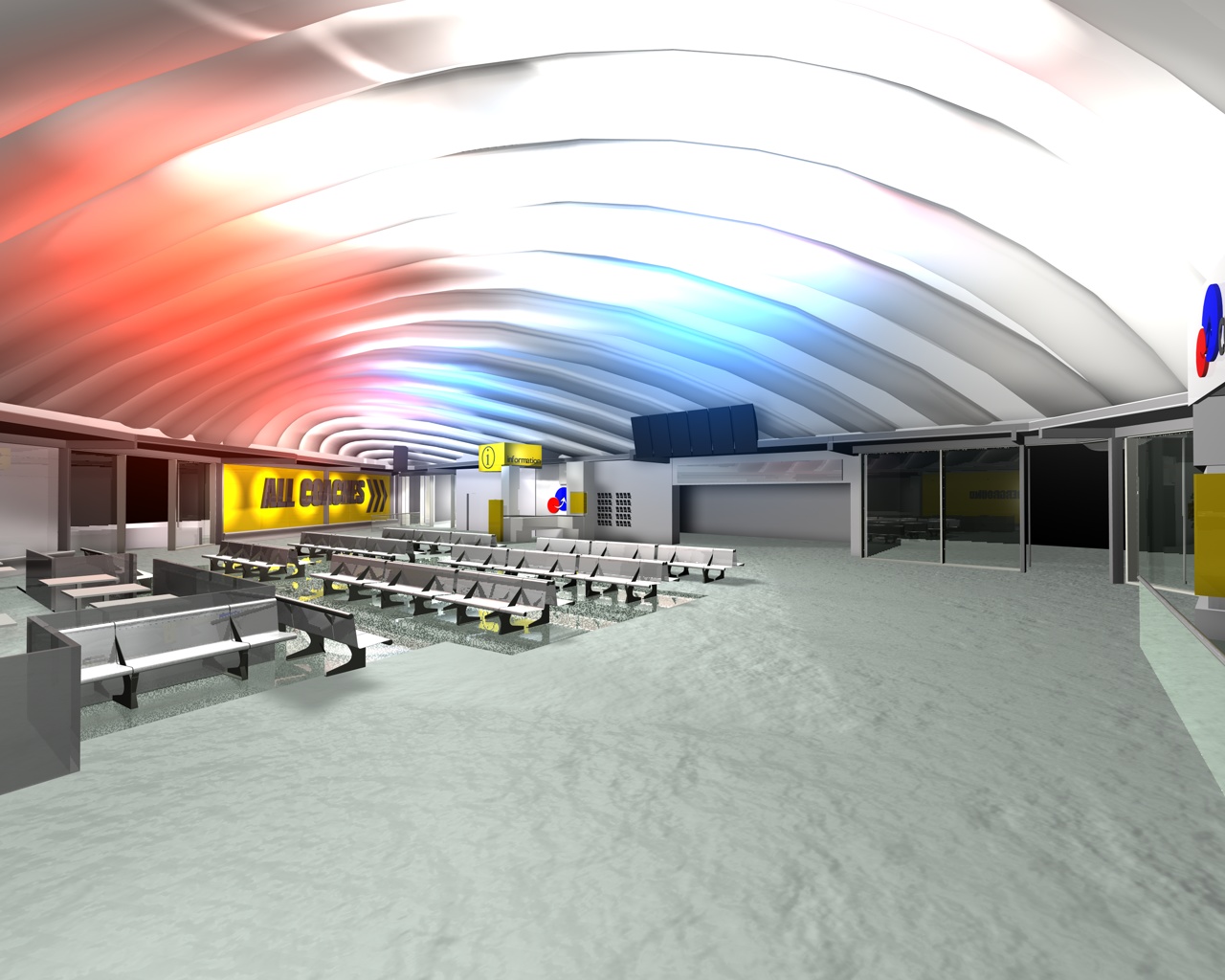

A visualisation of the completed interior

The team’s solution also had to be easy and quick to construct. “Two million passengers use the coach station a year, which was a major constraint. We had to maintain passenger movements with minimal disruption and no accidents,” explains Jim Bowyer, senior project manager at airport operator BAA.

“Traffic management was also critical as everything comes into the airport through the nearby tunnel. If this was obstructed in any way, before you knew it the tunnel would be blocked and it would back up the spur road and affect the M25. It can block the M25 in four minutes.” On top of these constraints, the team had to prove that this unprecedented structure would be safe.

Given these difficulties, why did the team opt for an inflatable roof? Well, it is incredibly light – just 120 g/m2 – yet capable of supporting up to two tonnes/m2. This meant it could easily span the 45 m of the concourse with a minimal support structure sitting on shallow foundations. Best of all, the roof could be prefabricated then installed overnight.

Crucially, the solution also had the architectural appeal designer D5 Architects was looking for. “National Express wanted an iconic structure that was very memorable,” explains Andy Hilton, an architect at D5. “We also wanted something that reflected the transient nature of the site. This will always be changing. It is very responsive to any wind movement and because it is translucent, it instantly reflects changes to the quality of the light.”

The building as seen by aerial passengers.

But there was a long way to go to realise this vision. “It was a bit of a pipe dream to start with. We knew what we wanted to do but we had to embark on quite a long investigation to get it to work,” says Hilton. In researching the idea, D5 Architects enlisted the help of balloon maker Lindstrand. The firm specialises in fabrics that are subject to tensile stress under pressure, such as round-the-world balloons and the parachutes needed to slow space probes landing on Mars. It has also built temporary inflatable structures. But most importantly for the team, Lindstrand had test facilities that could be used to prove the roof could meet Building Regulations. “We have extreme test labs and can simulate the environments of different planets,” says John Pattison, Lindstrand’s project manager. “But it’s been a tremendous challenge all the way as there were no standards to guide us.”

Lindstrand decided to stick to what it knew and used process standards and design standards approved for aircraft. This made the job even tougher, as aeroplanes are built to a more stringent “factor of safety” – that is, the ratio of the breaking stress of a structure compared to the maximum stress it is designed to resist in normal use. For a plane, this is four, whereas buildings usually make do with 1.5. The roof had to satisfy three key regulations governing wind, snow loading and fire. It proved difficult to model these conditions on computer because of the way fabric behaves under loading, so the only way to be sure the roof would perform was to build prototypes. “We designed and built five prototypes using different methods to find out which would give us the factor of safety we required,” says Pattison. “Each was tested to destruction, which wasn’t cheap, but we’ve achieved what we wanted.”

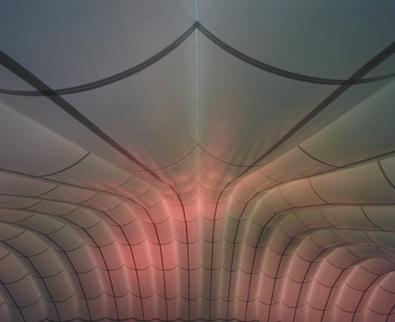

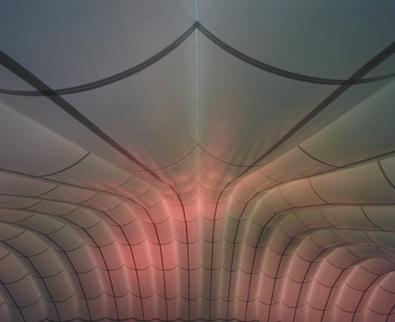

For starters, the roof has to be able to resist normal loads, including those imposed by wind or snow. These exert downwards, sideways and upwards pressures. Conventional roofs are inherently heavy, so uplift isn’t too much of a problem. This was not the case with this roof, as Ben Karunasekera, an associate at multidisciplinary consultant WSP Cantor Seinuk, explains. “The primary problem wasn’t the downloads but the uplift.” The fact that the roof was shaped like a wing did not help, either. The solution was to tie it down to its supporting steel structure (see “How the roof works factfile). The roof functions structurally as an arch made up of a series of tubes. The air pressure in these tubes is crucial for its structural integrity: if the roof loses pressure, down it comes. So what happens if it gets a puncture? The answer was to divide the roof into distinct zones or “cells” consisting of several tubes joined together. Lindstrand designed the roof so a punctured cell could be held up by the two on either side. The number of tubes making up a cell varies according to the span – the long span cells have fewer tubes, so it is easier for the adjacent cells to hold them up.

A series of round tubes makes up the striking inflatable roof

The high factor of safety means the danger of a roof collapse is extremely remote. If a section gets a puncture, sensors will increase the pressure in the adjacent tubes to compensate. A series of fans keep the tubes inflated to a normal working pressure of 0.5 pounds per square inch. Increasing the pressure increases the load the roof can take. The tubes can go up to 1 psi, which is more than enough to compensate, but the tubes have been tested up to 5 psi. Furthermore, there are backup fans that can blast air into the tubes to keep these pressurised in the event of a large puncture.

Fire resistance was the final challenge, because the roof is made from a PVC-coated fabric and regulations demanded it stay up for 30 minutes in the event of a fire. The zoned nature of the roof means a local fire can create a hole in the roof without a collapse and according to Pattison, the roofing material won’t support a naked flame – meaning fire couldn’t spread through the roof.

The team’s hard work has paid off: their design satisfied the planners and building control, the roof has been erected and work is continuing underneath on facilities in the concourse. For now, passengers flying into Heathrow are enjoying a unique view but Lindstrand hopes this will change. Having won the necessary approvals, it wants to create a new market for inflatable roofs so it won’t be long before they are popping up everywhere.

Heathrow coach station key points

The world’s first inflatable roof has just been completed at Heathrow’s National Express station

Roof very lightweight so needs minimal foundations and can be installed overnight

No standards existed, so the team had to develop a solution that met Building Regulations

How the roof works and how it was built

-

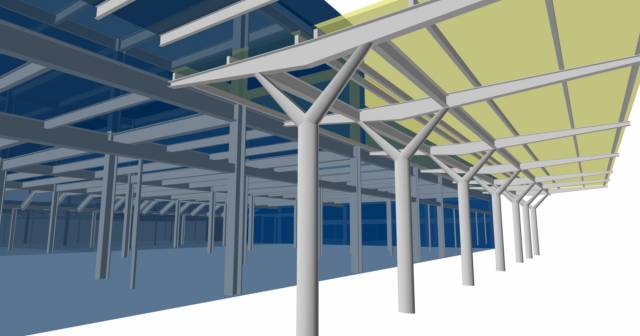

The inflatable roof is elegantly simple. It sits over an irregularly shaped space defined by a series of existing structures including lifts and a ticket office. The base is 4 m above ground level and sits on a ring beam supported on steel columns. It rises to a maximum of 9 m above ground. The ring beam closely follows the edges of the new concourse. “When the roof is loaded, it will try to spread out but the ring beam stops that – and it stops it lifting,” says Ben Karunasekera, an associate with WSP Cantor Seinuk. He adds that unlike more conventional structures, the roof will deflect under loading and divert the stress to other areas. Luckily, a newsagent and cafe were being built where these loads were most concentrated, which helped to strengthen the structure.

The tops of the steel columns have a T-shaped support structure. The base of the inflatable roof has a 1.5 m diameter tube or manifold running around its perimeter that sits on top of this platform. Restraint straps tie the inflatable roof to the ring beam. The rear half of the support platform has stainless steel tie rods that go down to the ground “like guy ropes on a tent”, according to Karunasekera. The manifold at the base of the inflatable roof has an inner and outer “skirt” that is attached to the leading edges of the support structure to create a neat finish. The roof has a life of five-10 years – at the end of this time Lindstrand will take it down and recycle it.

Three-night stand

The coaches had to keep moving so contractor Mansell only had between 10.30pm and 5am to work on the concourse. The steel frame was prefabricated with the 31 columns and foundations installed in sections over several months. Once it had finished the frame, the roof was ready to go on.

The roof was prefabricated by Lindstrand and brought to site on a lorry. “The conditions are very, very important,” says Allan Millward, Mansell’s project manager. “It has to be a still night with wind speeds no more than 5 to 6mph otherwise the roof could be taken up like a sail.” After several false starts, the team were ready to go.

The roof arrived rolled up like a length of carpet. It was lifted by crane up onto the ring beam on one side of the space and unfolded to its full 45 m length. The roof was installed by inflating it so it unfolded and then it was pulled by ropes across the void of the concourse.

This was done until the roof was sitting on its ring beam fully inflated and strapped down. The following night, it was adjusted to fit the structure and on the third night the skirt was fixed. Lindstrand’s Pattison is confident this time can be beaten. “On the basis of this experience we could install it, inflate it, tie it down and hand it over in one night,” he says.

|